Stage - Project Preparation:

First, we create your steel villa or prefabricated house projects by adhering to your wishes. We offer steel or prefabricated structure design suitable for regional conditions.

Stage - Pre-Production:

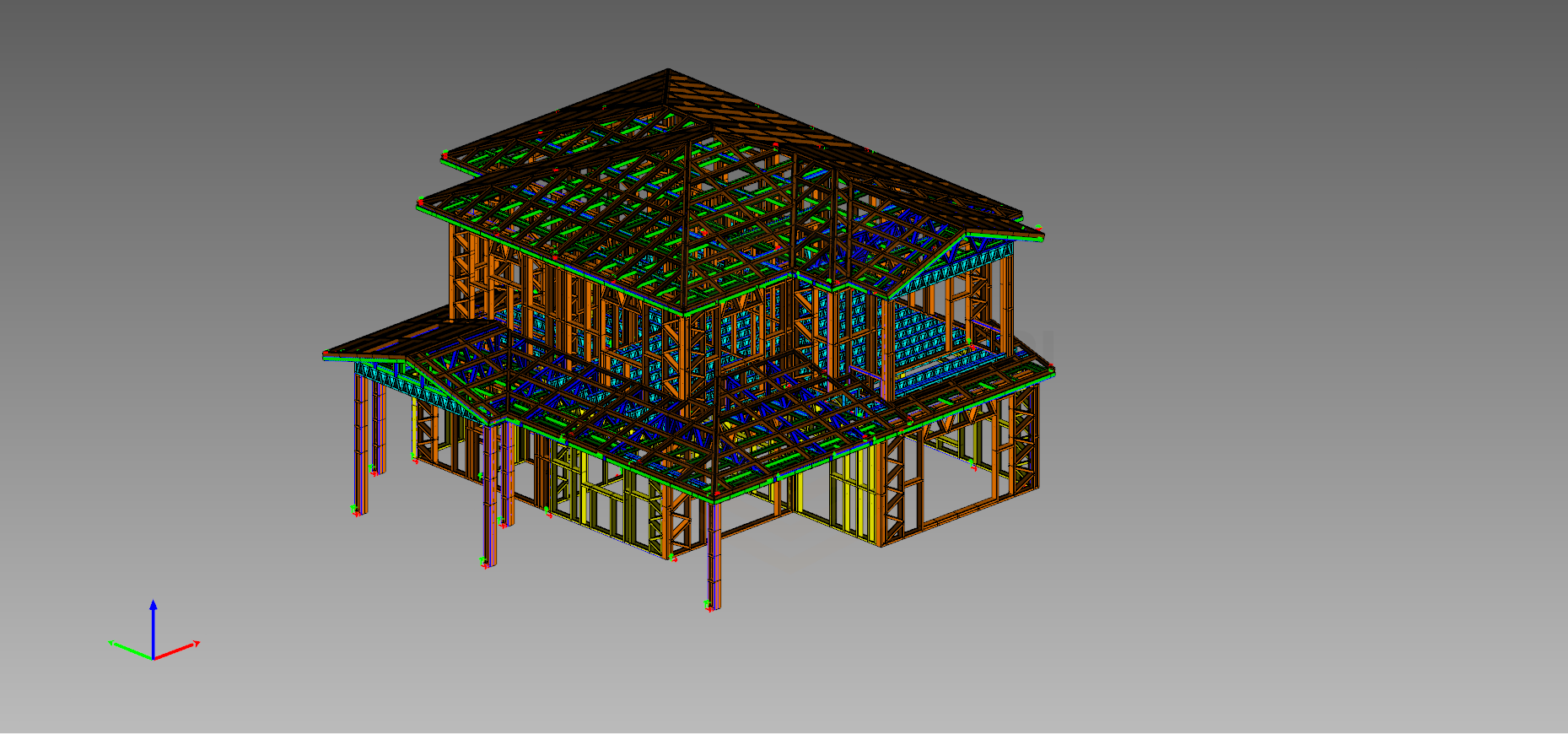

We prepare the steel construction or prefabricated structure with millimeter precision with the help of computer-controlled machines during the pre-production stage we carry out in our factory. We combine wall panels, truss panels, ceiling panels, roof panels and carrier columns with a rivet or bolt system, and then deliver them to the construction site. Installation using smart screws or bolts increases the building's resistance to earthquakes.

Stage - Building Cladding:

After the assembly of the steel building is completed, we start the exterior and interior cladding process. While the electrical and plumbing works are completed, the building cladding is finished with materials suitable for climatic conditions. After the isolation provided with rock wool and mineral wool, it is finished with the material determined for the roof covering.

Stage - Painting:

Primer and puttying or plaster is applied on the selected material on the exterior walls. On the interior walls, grouting plaster with mesh is applied to the joints and the final coat is painted.

Stage - Ceramic Application:

Ceramic application is performed on wet floors and patio floors upon request.

Stage - Finishing Works:

In the final stage, the finishing works are completed. Doors, windows, parquet and sanitary ware are applied, made in accordance with technical specifications and delivered.

In this process, we are working to provide you with reliable and durable solutions in steel structures. We are happy to share our experience that light steel design can add durability and aesthetics to your living spaces.

First, we create your steel villa or prefabricated house projects by adhering to your wishes. We offer steel or prefabricated structure design suitable for regional conditions.

Stage - Pre-Production:

We prepare the steel construction or prefabricated structure with millimeter precision with the help of computer-controlled machines during the pre-production stage we carry out in our factory. We combine wall panels, truss panels, ceiling panels, roof panels and carrier columns with a rivet or bolt system, and then deliver them to the construction site. Installation using smart screws or bolts increases the building's resistance to earthquakes.

Stage - Building Cladding:

After the assembly of the steel building is completed, we start the exterior and interior cladding process. While the electrical and plumbing works are completed, the building cladding is finished with materials suitable for climatic conditions. After the isolation provided with rock wool and mineral wool, it is finished with the material determined for the roof covering.

Stage - Painting:

Primer and puttying or plaster is applied on the selected material on the exterior walls. On the interior walls, grouting plaster with mesh is applied to the joints and the final coat is painted.

Stage - Ceramic Application:

Ceramic application is performed on wet floors and patio floors upon request.

Stage - Finishing Works:

In the final stage, the finishing works are completed. Doors, windows, parquet and sanitary ware are applied, made in accordance with technical specifications and delivered.

In this process, we are working to provide you with reliable and durable solutions in steel structures. We are happy to share our experience that light steel design can add durability and aesthetics to your living spaces.