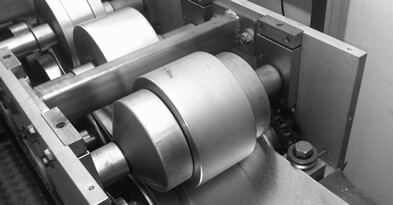

The mild steel production process requires a series of precision processes and advanced technology. This process first begins with the conversion of the steel material into a suitable form. Steel is cut and bent into a specific shape using precision machinery. This process makes the steel light and flexible, while maintaining its durability and strength.

After this stage, the steel construction elements are brought together. This process is usually performed under factory conditions and various methods are used to assemble the steel elements. Generally, the joining process is performed with a rivet or bolt system.

In the next stage, the steel structure elements are brought together to form a steel skeleton. This skeleton is designed to support the structure and is usually constructed using steel bars and plates. This process is usually performed by experienced and experienced personnel.

After the installation of the skeleton is completed, the structural elements are mounted on the building. This process is usually carried out together with the coating of the exterior and interior facades of the building and the completion of the electrical and plumbing works.

Finally, the insulation process of light steel structures is performed. This process is vital to protect the building from environmental factors and increase energy efficiency. Insulation is usually made with rock wool on the walls and mineral wool on the roof.

The light steel manufacturing process finally delivers a safe, durable and aesthetically appealing structure to the end user. This process includes quality control and continuous improvement at every step, so we can deliver the best results to our customers.